Commercial refrigerators are costly to replace, and unpredictable failures can cause food spoilage, energy waste, and operational losses. Commercial refrigerators generally last 8 to 15 years depending on build quality, usage intensity, and maintenance. Key factors include compressor durability, materials, temperature stability, and early warning signs that indicate declining performance.

Below is a complete professional guide to help understand lifespan, identify failure signs, and choose long-lasting refrigeration equipment.

What Is the Average Lifespan of Commercial Refrigerators?

Commercial refrigeration equipment is a key asset in retail and food service. Knowing its lifespan helps businesses plan replacement cycles and avoid sudden failures. Units made with strong materials and stable cooling systems usually last longer than light duty models.

Most commercial refrigerators work reliably for 8 to 15 years. The actual lifespan depends on the compressor quality and the design of the cooling system. Daily workload and the temperature around the equipment also affect long term durability.

Typical Lifespan of Common Commercial Refrigeration Equipment

Different refrigeration units face different levels of workload. The following overview help you compare typical service life and understand what influences each category.

| Equipment Type | Expected Lifespan | Notes |

|---|---|---|

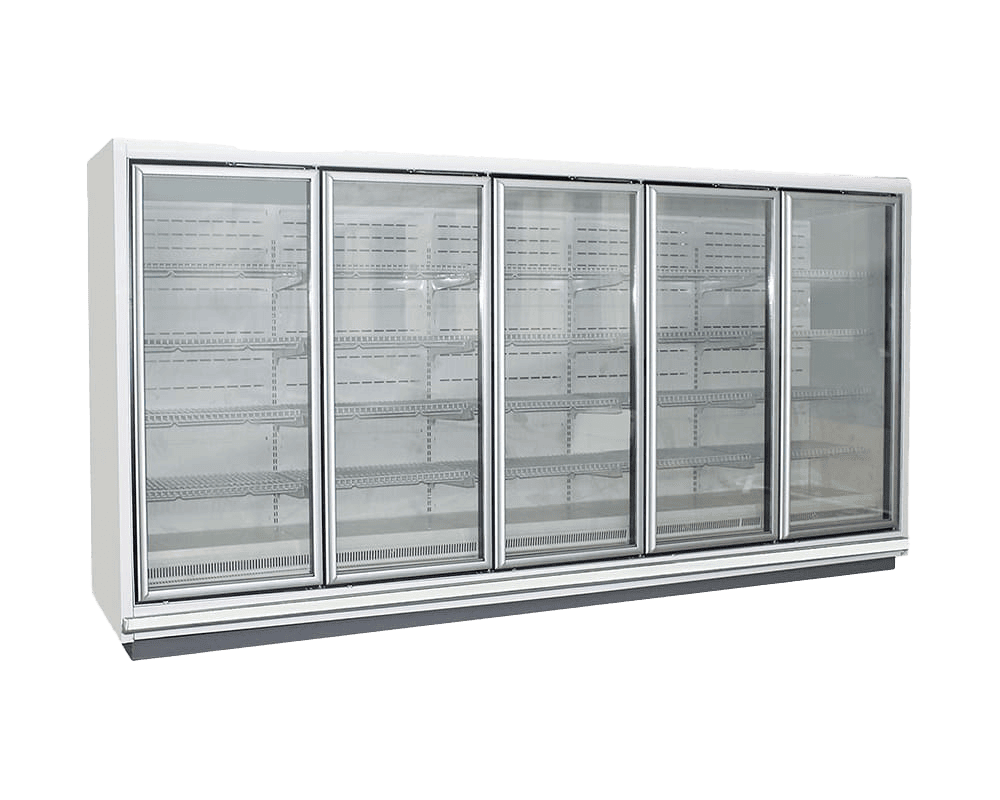

| Upright display refrigerator | 8–12 years | Frequent door opening increases wear |

| Open air curtain cabinet | 6–10 years | High air exposure raises cooling load |

| Fresh meat display case | 8–15 years | Stable cooling performance is important |

| Island freezer | 10–15 years | Strong insulation supports longer service life |

| Bakery and beverage display | 8–12 years | Temperature changes can affect durability |

Tip: Regular cleaning of the condenser and proper ventilation can help extend the life of these systems. Good maintenance also reduces energy use and improves long term performance.

What Factors Affect Refrigerator Lifespan?

Understanding what affects a commercial refrigerator’s lifespan helps businesses plan maintenance and replacements. The following examines the main factors that determine durability, from construction quality to usage conditions and routine upkeep.

Design and construction: Stainless steel units, including top freezer models, resist corrosion better and maintain mechanical stability. A reliable cooling system with a high-quality compressor reduces operational load and supports longer service life. Units built with robust materials and well-engineered components generally last longer in continuous operation.

Usage and environment: Daily usage frequency, storage load, ambient humidity, and temperature changes directly influence durability. High door-opening rates or overloading can increase strain on the compressor and cooling system. Maintaining consistent operating conditions helps prevent premature wear and ensures stable performance.

Performance enhancements: Equipment with energy-efficient controllers, high-performance coils, and sturdy frames performs better in demanding retail environments. Advanced systems reduce energy consumption while maintaining temperature accuracy. Such features contribute to longer operational life and lower maintenance costs over time.

Usage and maintenance: Proper use and regular maintenance are critical to extending refrigerator lifespan. Routine tasks include cleaning condensers and coils, monitoring temperature, and checking seals for wear. Consistent upkeep prevents component failures, reduces energy consumption, and helps maintain optimal cooling efficiency.

How Can You Tell If Your Refrigerator Is Going Out?

Recognizing early warning signs helps prevent food spoilage and unplanned downtime. Retailers and operators should monitor the following indicators to detect potential refrigerator failure before it becomes critical.

Fluctuating temperatures: Irregular or unstable temperatures are one of the first signs of a failing refrigerator. Units that cannot maintain consistent set points may indicate issues with the thermostat, refrigerant levels, or compressor efficiency. Continuous monitoring allows early intervention before products are compromised.

Extended cooling cycles: When compressors run longer than usual to reach target temperatures, it signals that the system is working harder than normal. This increased strain can be caused by worn components, poor airflow, or low refrigerant.

Unusual noise: Loud or abnormal operating sounds often point to mechanical problems in the compressor, fans, or other moving parts. Detecting these noises early can help schedule maintenance before parts fail and reduce costly downtime.

Excessive frost or Ice build-up: Frost or ice accumulation on evaporators, shelves, or coils can restrict airflow and reduce cooling efficiency. This may result from defrost system failure, poor door seals, or excessive humidity.

Rising energy consumption: Unexpected increases in electricity usage can indicate inefficiency caused by compressor overwork, poor insulation, or blocked coils. Monitoring energy trends helps operators detect failing components and plan preventive measures.

Drainage and alarm indicators: Unpleasant odors from drain pans or repeated alarm alerts signal declining system performance. Drain blockages, condensate buildup, or sensor malfunctions can compromise food safety if not addressed promptly.

Monitoring these signs and implementing regular maintenance ensures reliable operation, protects inventory, and extends the service life of commercial refrigeration equipment.

How Can You Extend the Service Life of Your Supermarket Refrigerators?

Proper maintenance and disciplined operation are essential to maximize the lifespan of supermarket refrigerators. By addressing both mechanical checks and operational practices, equipment can maintain optimal performance and reduce costly downtime.

1. Regular Condenser Maintenance

The condenser coil is critical for efficient cooling. Dust and debris accumulation can drastically reduce heat exchange, forcing compressors to work harder. Regular cleaning and ensuring adequate ventilation around the back panels help maintain proper cooling efficiency and reduce overall energy consumption.

2. Door Gasket and Seal Checks

Door gaskets prevent cold air from escaping the unit. Leaks can make compressors run continuously, accelerating wear and increasing energy costs. Inspect gaskets regularly and replace any damaged or worn seals to maintain airtight closures and stable internal temperatures.

3. Fan Motors, Thermostats, and Defrost Systems

Fans circulate cool air throughout the refrigerator, while thermostats regulate temperature and defrost systems prevent ice buildup. Routine inspection ensures these components function correctly, maintaining even cooling, reducing frost formation, and minimizing compressor strain.

4. Drainage and Water Management

Blocked drains can lead to water accumulation, causing hygiene issues and potential equipment damage. Clearing drainage channels regularly and ensuring proper alignment in display units prevents leaks and maintains optimal operation.

5. Product Placement and Airflow

Correct product placement is vital for efficient airflow. Overloading shelves or placing items too closely can obstruct circulation, causing uneven cooling and increased stress on compressors. Adequate spacing ensures consistent temperatures and reduces energy consumption.

6. Operational Discipline

Staff behavior significantly impacts refrigerator longevity. Minimizing frequent or prolonged door openings, maintaining consistent temperature settings, and following stable defrost cycles all reduce compressor workload and help maintain optimal performance.

In Conclusion

Commercial refrigerators typically last 8 to 15 years, depending on quality, maintenance, and usage intensity. Choosing durable construction and a reliable manufacturer ensures long-term performance and reduced operational risks. When your supermarket refrigerator is completely worn out or you need to buy a new one, please contact eddysen for our wide variety of supermarket refrigerators.

Frequently Asked Questions

How Can OEM and ODM Quality Influence Refrigerator Durability?

High-quality OEM and ODM manufacturing ensures precise assembly, reliable compressors, and durable materials. Certified production and quality control provide consistent performance, reducing breakdowns and extending the equipment’s lifespan.

How to Choose a Long-Life Refrigerator for Your Retail Business?

Focus on compressor brand, insulation quality, stainless steel construction, energy efficiency, and supplier reliability. Well-built units with strong after-sales support last longer and reduce maintenance costs.

What Is the Most Common Cause of Refrigerator Failure?

Compressor failure is the most frequent cause, often triggered by poor maintenance, dust-clogged condensers, or continuous overwork from high-traffic environments.